If we want to know about color production theory of LED backlight, we must learn about LED lamps first. The colors of LED backlight are composited by the colors of LED lamps we are going to use.

First, how can we choose what kind of LED lamp we should use?

Basically, there are 3 main points to determining a LED lamp.

1. The size and packing of the LED lamp.

We can divide LED lamps into DIP LED and SMD LED according to the style of packing.

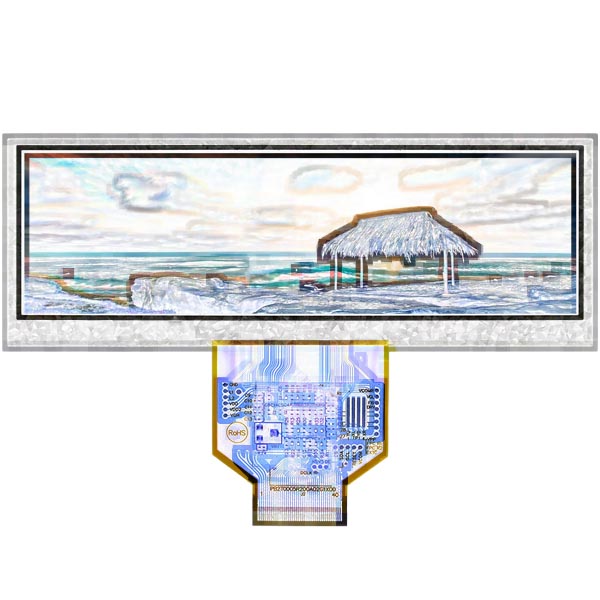

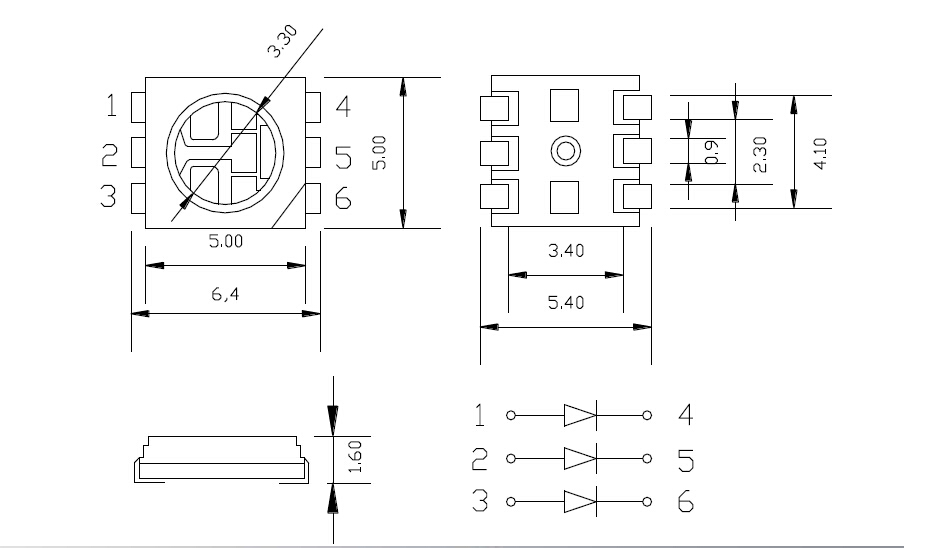

Please see the picture below, which is the blueprint of 5050 SMD.

We usually name the SMD according to their length and width. For example, we call length 5.0 mm and width 5.0 mm SMD as 5050 SMD, and length 3.5 mm and width 2.8 mm SMD as 3528 SMD.

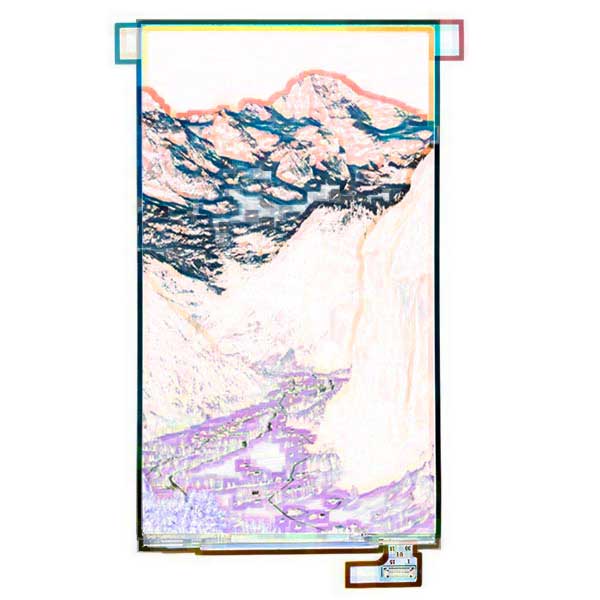

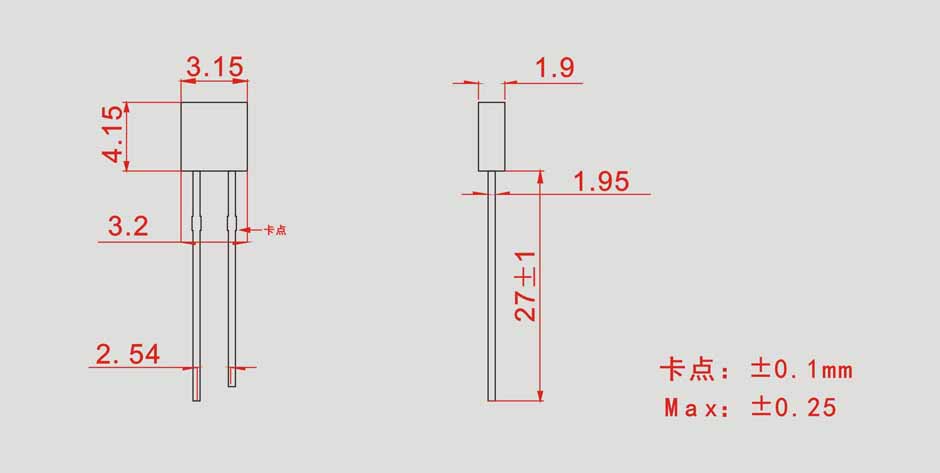

There are some pictures of DIP LED below.

SMD is a lot smaller than DIP if they adopt the same LED chips.

| Item | DIP LED | SMD LED |

| Volume | large | small |

| Weight | light | lighter |

| Using time | long | longer |

| Heat radiation | better | good |

| Reliability | high | higher |

| Anti-vibration ability | strong | stronger |

| Soldering defect rate | low | lower |

If we say that LED is the future of illumination, we can also say that SMD is the future packaging of LED.

2. The indexes of illumination.

There are so many indexes of illumination, but we mainly use two indexes: Luminous flux and Luminous intensity.

Luminous flux is that light which is emitted by a light source in some amount of time. It is usually the total amount of the light which is transformed in 1 watt hour (electricity power). The greater luminous flux of the light source, the more the light is emitted.

If we compare the luminous flux and luminous intensity of illumination units to the force and pressure of the mechanical units, we can regard luminous flux as force and luminous intensity as pressure.

In order to make illuminated points much brighter, we not only should increase the luminous flux, but also should decrease the illuminating area, so that we can get a better luminous intensity.

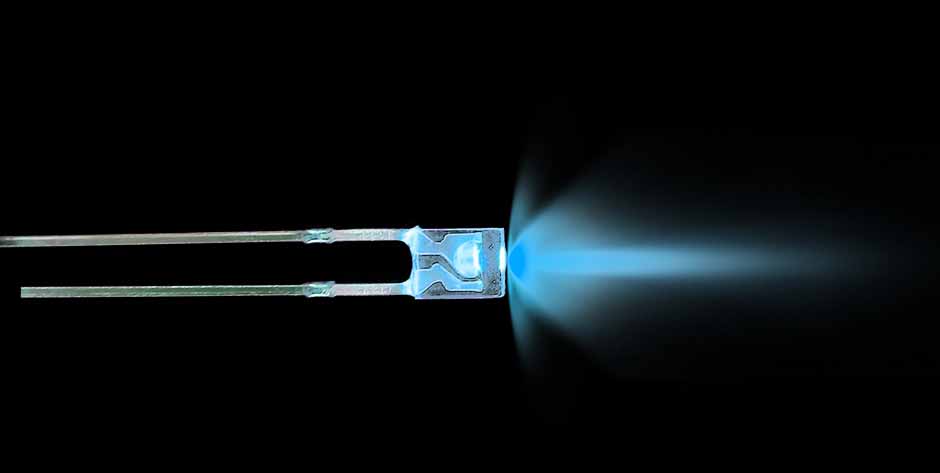

Look back to our last example. SMD LED has a wider beam angle, hypothetically, they are using the same LED chips, which means they have almost the same luminous flux, so DIP LED has a better luminous intensity.

The unit of luminous flux is LM. Generally, it is used to measure the brightness of the light. At present, the luminous flux of small power (0.06-0.08w) is 2-10LM; the luminous flux of middle power (0.2-0.3w) is 10-25LM; the luminous flux of high power (0.5-1w) is 50-200LM; the luminous flux of super high power can reach more than 200LM.

Human eyes have different feelings to different colors of light. For example, we are very sensitive to yellow-green light whose wavelength is 555 nm. 1W = 683 LM means that 1 watt of electricity power transforms into 683 LM yellow-green light. Meanwhile, we can’t see infrared and ultraviolet and we are not sensitive to red light. It is only 73 LM/W, which means 1 watt of electricity power transforms into 73 LM red lights whose wavelength is 650 nm. It is very complicated for white light which has many different spectra.

Luminous intensity is that luminous flux per solid angle in a specific direction.

Please see the formula below.

I=Φ/Ω

Φ: Luminous flux

Ω: Solid angle.

Luminous intensity is a criterion that can describe how bright the light source is. The higher the luminous intensity, the brighter the light source and the objects which are illuminated by the light source in the same conditions will be.

The unit of luminous intensity is mcd. For example: 1000 mcd = 1 cd and 15000 mcd = 15 cd. That is because the luminous intensity of LED lamps is very low in the primary stage.

By the way, I want to talk something about the photoelectric conversion efficiency, which is a whole new other topic and my customers ask me about it all the time. We continue our example: 683 LM yellow green light with 555 nm wavelengths. I am sorry to tell you that it is not going to happen because this is just a theory. Practically, it is less than 200 LM per watt, even in a lab. When we talk about the so called “high illumination LED lamp”, as a matter of fact, it has a relatively higher photoelectric conversion efficiency, which means it can release more visible light energy when it consumes the same amount of electricity power because it has a better chip. For example: the most commonly used LED lamp is about 100 LM per watt; meanwhile, the high laminating LED lamp is about 140-150 LM per watt. How can we improve the photoelectric conversion efficiency? This is an international technical problem. As far as I know, only time can solve this problem. It has been improving since the day LED was invented.

3. Wavelength and color temperature

|

Color |

Wavelength |

Luminous flux |

Voltage |

Current |

|

RED |

630-660 nm |

50-150 LM |

1.8-2.3 V |

15-20 am |

|

Orange |

580-590 nm |

50-150 LM |

1.8-2.3 V |

15-20 am |

|

Yellow |

560-570 nm |

50-150 LM |

1.8-2.3 V |

15-20 am |

|

Chartreuse |

566-575 nm |

50-150 LM |

1.8-2.3 V |

15-20 am |

|

Green |

500-535 nm |

50-150 LM |

2.6-3.4 V |

15-20 am |

|

Blue |

450-480 nm |

50-150 LM |

2.6-3.4 V |

15-20 am |

|

Purple |

440-460 nm |

50-150 LM |

2.6-3.4 V |

15-20 am |

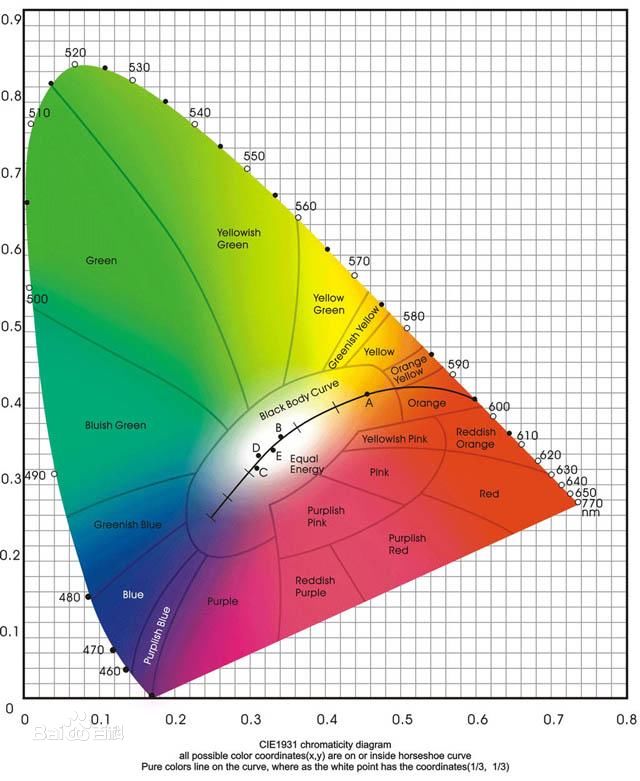

Each color corresponds to a certain range of wavelength. Please see the picture blew.

I am going to give a quick introduction to CIE chromaticity coordinate. The horizontal means blue and red line, the bigger the value, the redder it becomes; the smaller the value, the bluer it becomes. The vertical means the blue and green line, the bigger the value, the greener it becomes; the smaller the value, the bluer it becomes. You can see the middle white part which has a wide range in the picture. It is white light that can’t be described with wavelengths. But we can only describe it by color temperature or chromaticity coordinates.

(C) = R (R) + G (G) + B (B)

This is the color matching equation. Theoretically, any color can be made by Red, Green, and Blue three colors.

4. Other photoelectric parameters

Absolute Maximum Ratings(Ta=25℃)

|

Items |

Symbol |

Absolute maximum Rating |

Unit |

| Power Dissipation |

PD |

200 |

mW |

| Forward Current(DC) |

IF |

60 |

mA |

| Peak Forward Current |

Ifp |

150 |

mA |

| Operation Temperatur |

Topr |

-20~+80℃ |

℃ |

| Storage Temperature |

Tstg |

-40~+100℃ |

℃ |

| Soldering Temperature |

Tsol |

Max.260℃ for 3 sec Max |

|

Typical Electrical & Optical Characteristics(Ta=25℃)

|

Symbol |

Condition |

Min. |

Typ. |

Max. |

Unit |

|

| Luminous Flux |

Lumens |

If=60mA |

10 |

12 |

lm |

|

| Forward Voltage |

Vf |

If=60mA |

3.0 |

3.3 |

3.6 |

V |

| Luminous Intensity |

Iv |

If=60mA |

20 |

— |

22 |

LM |

| Reverse Current |

Ir |

VR=5V |

— |

— |

10 |

μA |

| Viewing Angle |

2θ1/2 |

If=60mA |

— |

120 |

— |

deg |

| Color temperature |

TC |

If=60mA |

2800 |

3200 |

K |

Please see the two tables above. These parameters are the using conditions of LED lamps. Most of the parameters are mentioned before. Only one parameter is special- Reverse Current.

How can LED lamps be driven by Reverse Voltage? Of course, it can’t. Normally, when LED lamps are driven by Forward Voltage, they can be lit and we can test the current. When LED lamps are driven by Reverse Voltage, they can’t be lit and there will be no current. Before the LED lamps are shipped, we will use very high reverse voltage to test them. For example 5V or 20 V. If the reverse current is less than 10μA, they are qualified.

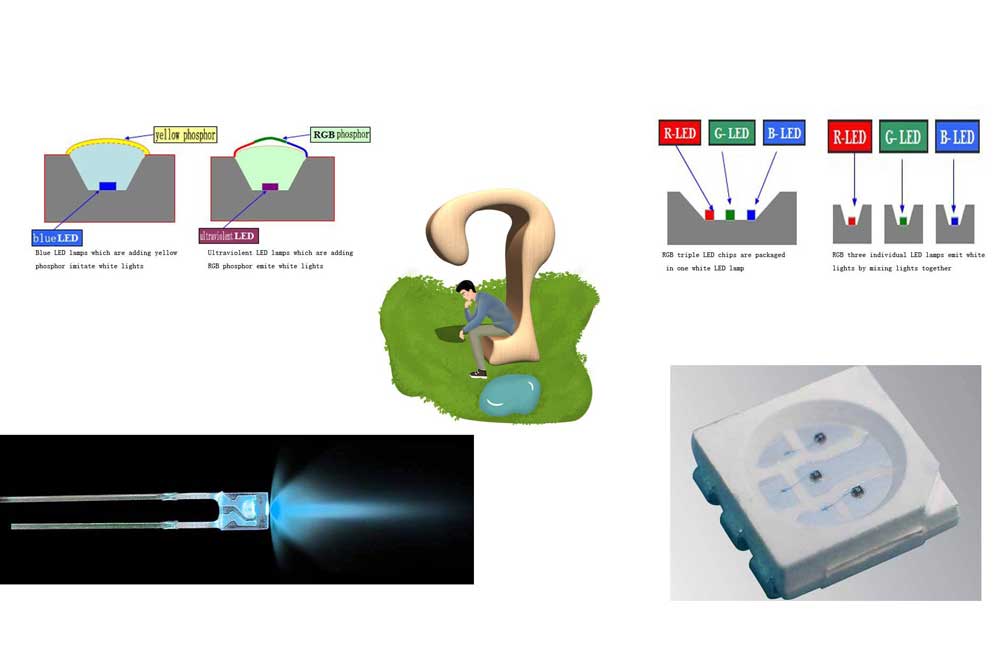

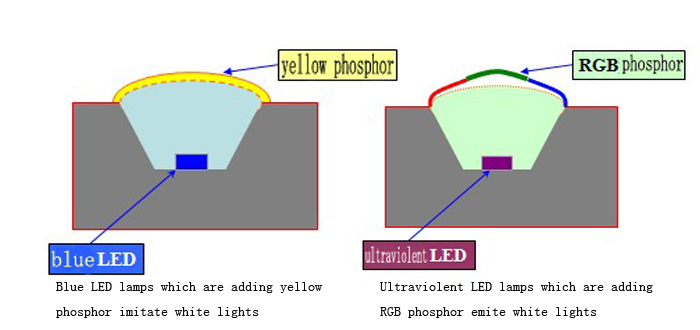

5. As I mentioned before, white LED lamp is special. How can we make it? There are 4 different kinds of methods we can use.

5.1 Blue LED lamps that are adding yellow phosphor emit white light.

Advantage: It has a simple structure and high luminous efficiency.

Disadvantage: It lacks red light and has a poor reduction which is only about 65%.

5.2 Ultraviolet LED lamps that are adding RGB phosphor to emit white light.

Advantage: It has a better reduction.

Disadvantage: It accelerates the aging process of epoxy resin and phosphor.

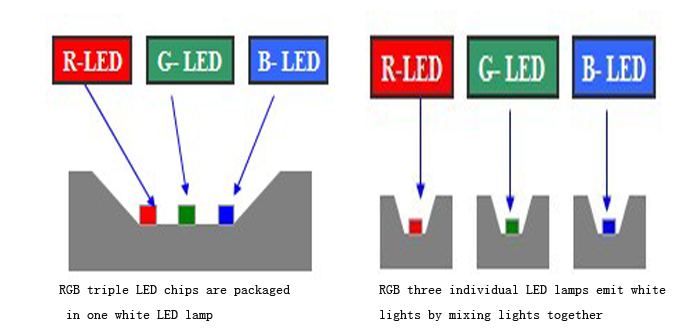

5.3 RGB triple LED chips are packaged in one white LED lamp.

Advantage: The structure of LED lamp is close and does not need external light.

Disadvantage: It is affected a lot by the current and the heat dissipating. And it has some problems when packaged with good performance chips.

5.4 RGB three individual LED lamps emit white light by mixing lights together.

Advantage: It has an individual dissipating heat structure and high-efficient output of light.

Disadvantage: It requires a dedicated mixing light structure which will increase the cost.

Method 1 is the most commonly used because it is the cheapest.

6. Finally, how can we make the multicolor we want in LED backlight?

6.1 It is the simplest one that we use a LED lamp for each particular wavelength.

Please look back at the wavelength and color temperature section. It is easy, but we usually don’t use this method. For example: if we want 7 colors (Red, Green, Blue, Yellow, Cyan, Pink and White) in one LED backlight, so we have 7 different kinds of colors of LED backlight. It is too expensive. Besides, we may not have enough space to install so many LED lamps.

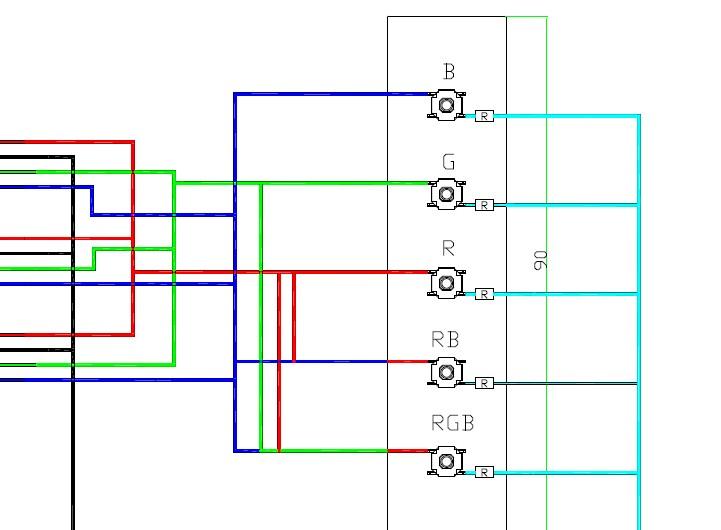

6.2 Use RGB 3 colors to make any kind we want.

| Red | + | Green | = | Yellow | ||

| Green | + | Blue | = | Cyan | ||

| Blue | + | Red | = | Pink | ||

| Red | + | Green | + | Blue | = | White |

See the blueprint below:

If we manually make RBG 3 colors in permutation and combination, we can only make 7 colors. And theoretically, we can make thousands of colors by RGB. But how? The answer is simple. We use an electronic controller which can regulate the input voltage to manipulate the luminous intensity of RGB LED lamps. Therefore, we can use RGB 3 LED lamps through an electronic controller to make almost any color we want. Life is full of possibilities, isn’t it?